Praxissoftware tomedo®

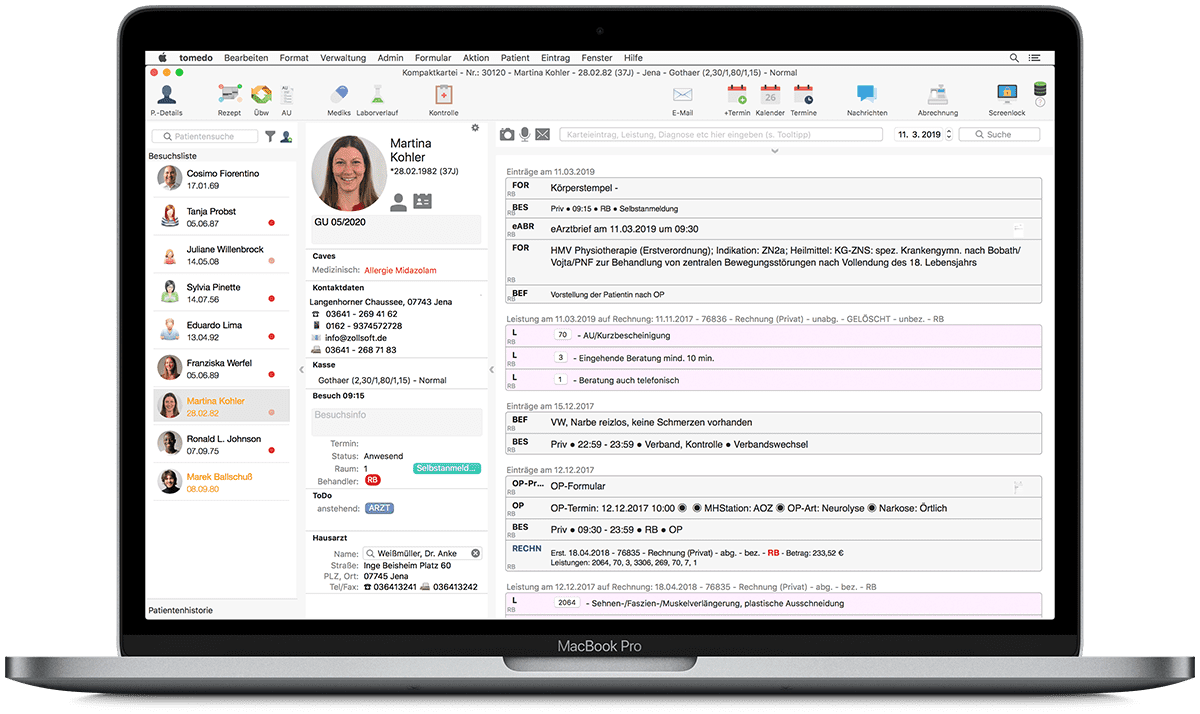

Die Praxissoftware tomedo® wurde von Ärzt:innen entwickelt und bietet als schnelles, stabiles und innovatives Praxis-Programm alles, was Sie für die effiziente Organisation Ihrer Praxis brauchen. tomedo® Praxissoftware ist exklusiv für Apple-Geräte programmiert.

Eine Praxissoftware

für alle Fachrichtungen

Unsere Praxissoftware hat viele Funktionen, die Sie in Ihrer (Privat-)Arztpraxis benötigen. Von TI-Funktionalitäten über Spracherkennung bis hin zur einfachen Abrechnung – unsere Software bringt Erleichterung für Ihren Praxisalltag.

Geräteanbindung

Per GDT, DICOM oder Dateilauscher können wir nahezu jedes diagnostische Gerät an unsere Praxissoftware anbinden, auch aus der Windows-Welt.

Hardware

Nativ für Apple-Hardware entwickelt ist die Praxissoftware stabil, schnell, flexibel, sowie effizient und hält Apps für iPhone, iPod, iPad und Apple Watch bereit. Windows-Server können bei einem Umstieg auf tomedo® in der Regel weiter verwendet werden.

Datenübernahme

Wir bieten Ihnen im Rahmen einer kostenlosen und unverbindlichen Test-Konvertierung eine hundertfach bewährte Datenkonvertierung aus einer Vielzahl anderer Praxisverwaltungssysteme.

Zertifizierung

tomedo® ist für Kassenabrechnung (HzV & andere Facharzt- und Selektivverträge), Privatabrechnung (GOÄ, GebüH inkl. PVS/PAD- und DATEV-Export) und BG-Abrechnung (UV-GOÄ inkl. Dale-UV) zugelassen.

Anwender entwickeln mit

Unser Team von über 100 Softwareentwicklern (davon rund die Hälfte promovierte Naturwissenschaftler) steht parat für Ihre Entwicklungen aller Art.

Praxissoftware tomedo®:

Einzigartige Funktionen

To-do-Konzept

Effizienter Praxis‑Workflow

Über blitzschnelles Verschieben von To-dos haben Sie immer im Blick, welcher Patient gerade von wem in welchem Raum behandelt wird. Mit selbst konfigurierbaren Aktionsketten können Ihre Mitarbeiter sich an den möglichen Arbeitsabläufen entlanghangeln.

Aktionsketten

Unendliche Möglichkeiten

Mit Aktionsketten können Sie in unserer Praxissoftware immer wiederkehrende Abläufe automatisieren. Dabei können ganz unterschiedliche Dinge wie z.B. Karteieinträge, Rezepte, Briefe und vieles mehr ausgelöst werden. Aktionsketten sind ein mächtiges Werkzeug für effiziente Praxen.

Künstliche Intelligenz

Selbstlernende Abrechnungsvorschläge

Mit Hilfe modernster Algorithmen aus dem Bereich des „Deep Learning“ schlägt Ihnen tomedo® passende Abrechnungsziffern aus dem EBM-, GOÄ- oder ICD-Katalog vor. Je nach Karteieintrag, Diagnose oder To-do werden so immer die idealen Abrechnungsziffern kombiniert. Optimal auch für die Privatpraxis!

Videosprechstunde Zum Produktvideo

Zum Produktvideo

Online Patienten behandeln

Patienten können in einem Videochat von Ärzt:innen verschiedener Fachrichtungen online behandelt werden. Während der Videosprechstunde haben Sie Zugriff auf die digitale Patientenakte in tomedo® und können so Dateien austauschen, chatten, zeichnen und sich Notizen machen. Diese Daten werden im Anschluss automatisch in der Patientenakte hinterlegt.

Online-Terminkalender Zum Video

Zum Video

Terminvergabe über Ihre Praxiswebseite

Patienten können, egal ob mobil oder zu Hause, über Ihre Webseite Termine vereinbaren. Dazu lässt sich der Online-Terminkalender einfach in Ihre Webseite integrieren, an Ihr Design anpassen und synchronisiert sich in Echtzeit mit dem tomedo®-Kalender auf dem Mac, iPad oder iPhone.

Immer up to date

Automatische Updates

tomedo® bietet die Möglichkeit, sich komplett automatisch selbst upzudaten, z.B. immer nach der Sprechstunde um 19 Uhr. Sowohl der Server als auch alle Arbeitsplätze können somit schnell und geräuschlos außerhalb der Sprechzeiten auf den neuesten Stand gebracht werden, ohne dass sich Mitarbeiter:innen in der Praxis aktiv darum kümmern müssen. Einfach passenden Rhythmus der Updates in tomedo® (täglich, wöchentlich, monatlich) auswählen und fertig.

Weitere Funktionsbereiche

der Praxissoftware

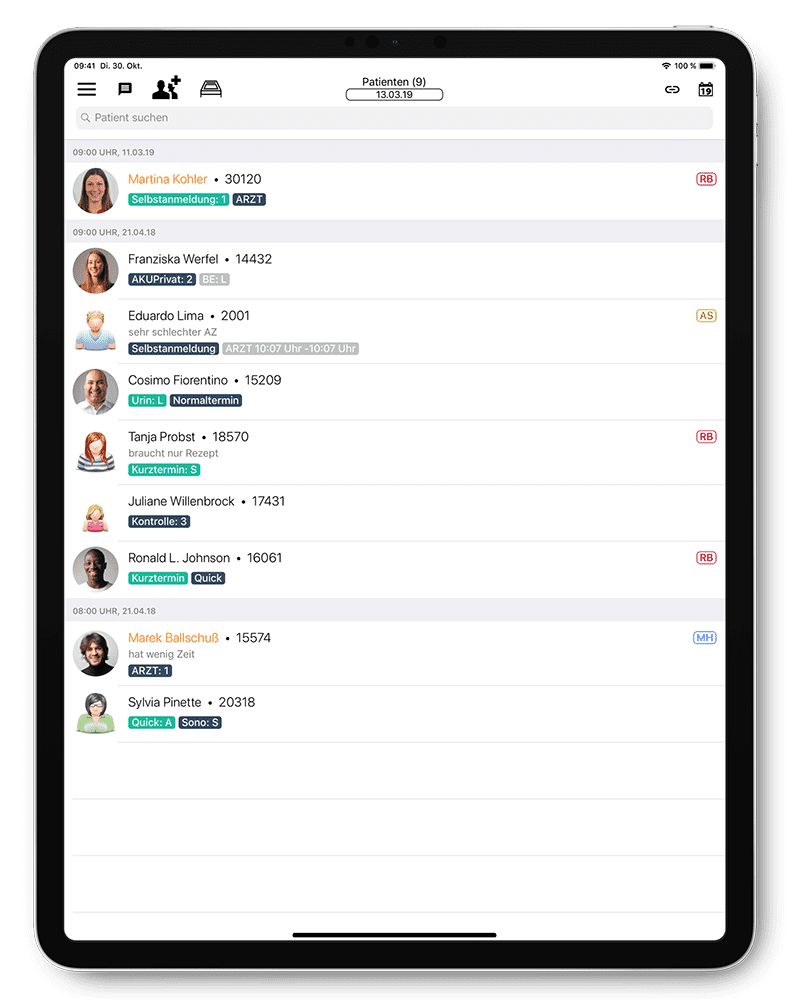

- Tagesliste

- iPad Aufklärungs- & Anamnesebögen

- Selbstanmeldeterminal

- Patienten-Stammdaten

- Patientenaufrufsystem

- Erinnerung an Vorsorgeuntersuchungen

- Diagnostische Anbindung

- Labordaten

- Video- und Bilddokumentationssystem intellimago

- ABDA-Medikamenten- & Hilfsmitteldatenbank

- Heilmittelbudget

- BMP mit Barcode-Scanfunktion

- Hausapotheke

- Blankoformulardruck

- Briefvorlagen

- Serienbriefe

- Textbausteine

- e-Arztbrief (KIM)

- Impf-Dokumentation

- 1-Klick-Abrechnung

- Live-Abrechnungsfehlerliste

- HzV & S3C-Verträge

- Privatrechnung (PAD-Anbindung)

- HKS & FEK

- Arbeitszeiterfassung

- Dienst- und Urlaubsplaner

- Messenger mit Chat

- (Online)-Praxiskalender

- Statistik-Modul

- Telefon- & Faxanbindung

- Auto-Updates

- Gesichts-Login

- Einzelplatzlösung

- Backup-Verwaltung

Onlinepräsentation

Wir laden Sie jederzeit gerne zu einer kostenlosen, unverbindlichen Live-Onlinepräsentation ein. Dabei führen wir Sie live während eines Videotelefonats in einer kurzweiligen Stunde durch unsere Arztsoftware tomedo® und gehen detailliert auf die Funktionen und Punkte ein, die Ihnen besonders wichtig sind.

Danach haben Sie sicherlich ein gutes Gefühl dafür, wie tomedo® Ihren Arbeitsalltag erleichtern kann. Sie werden überrascht sein, welche enormen Möglichkeiten Ihnen die Praxissoftware bietet.

Grenzenlos Mobil

Die Praxissoftware tomedo® macht nicht nur in Ihrer Praxis eine glänzende Figur. Auch zu Hause oder beim Hausbesuch kann der volle Funktionsumfang genutzt werden.

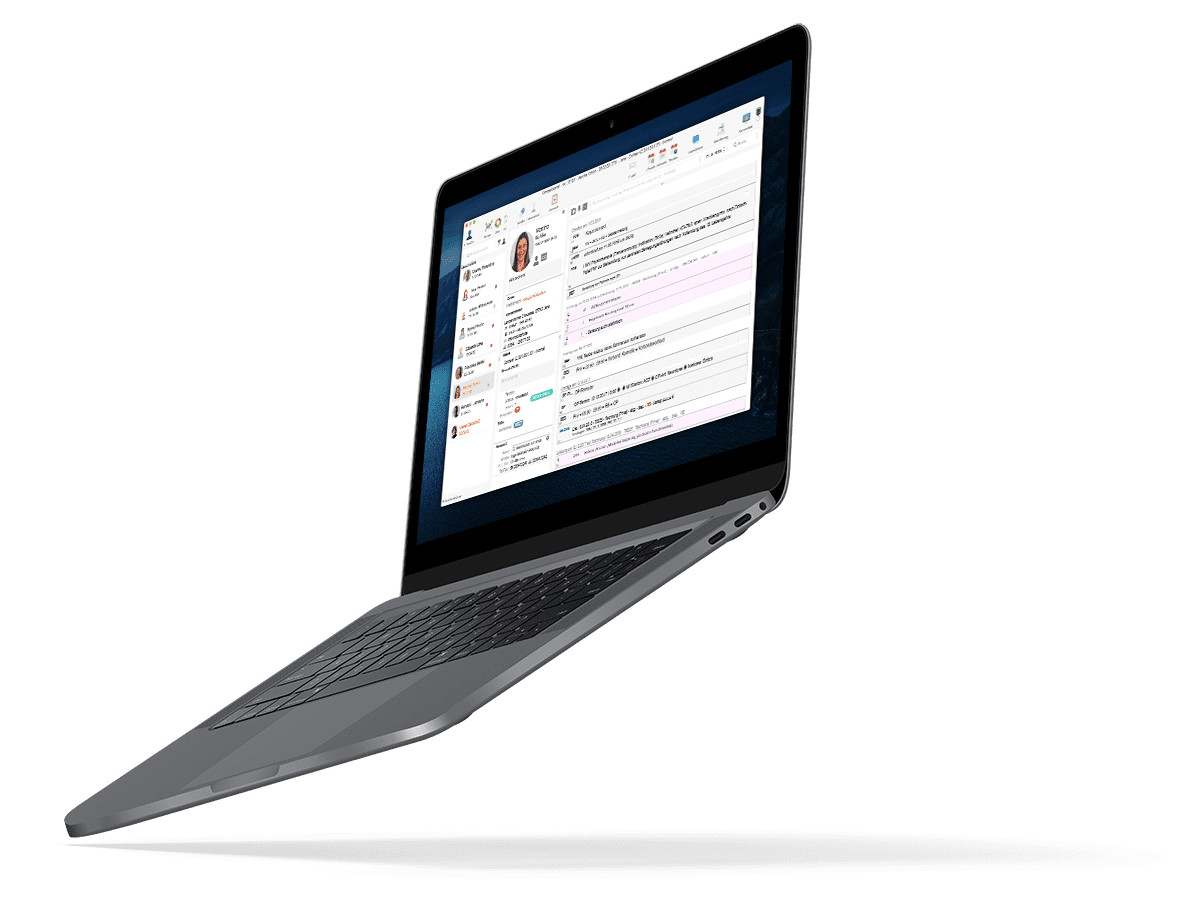

Praxissoftware unterwegs

Bequem zuhause arbeiten, für den Rezept-Druck vor Ort beim Patienten oder als mobile Einzelplatzlösung: Auf einem MacBook können Sie den vollen Funktionsumfang unserer Arztsoftware jederzeit nutzen.

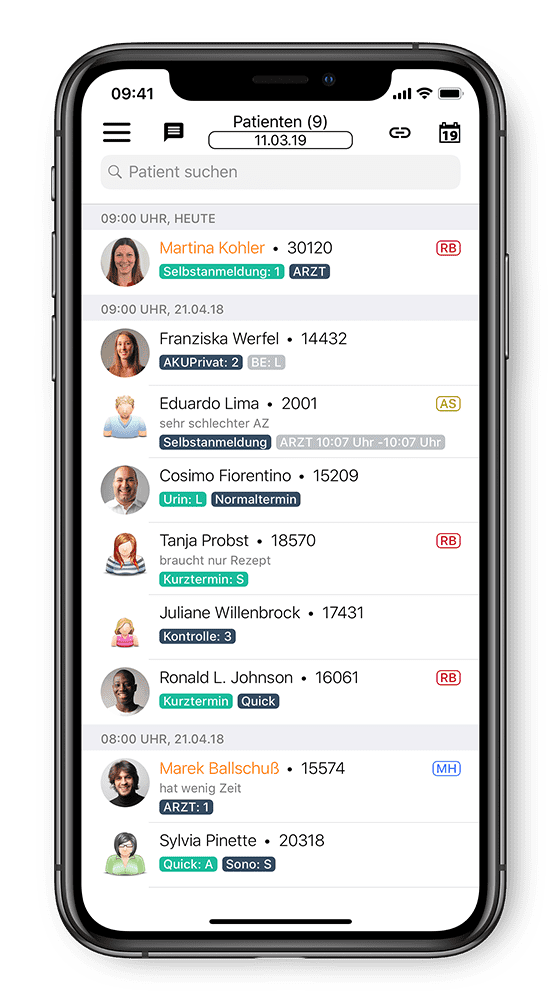

Praxissoftware auf dem iPhone

Aus der Akte die Navigation für Hausbesuche starten, Befunde per Siri diktieren, unterwegs Termine für den nächsten Tag checken: Die tomedo® iPhone-App ist einfach praktisch. Fotos direkt in die Akte schießen geht natürlich auch.

Praxissoftware auf dem iPad

Papierlose Praxis? Läuft! Wenn Sie digitalisierte Dokumente vom Patienten auf dem iPad unterschreiben lassen, speichert tomedo® zusätzlich die Druckspur und weitere Parameter der Unterschrift.

Praxissoftware am Handgelenk

Klein, aber oho: Mit der tomedo®-App für die Apple Watch können Sie Nachrichten über den tomedo®-Messenger empfangen, den nächsten Patienten in der Tagesliste sehen und einiges mehr.

Nutzererfahrungen

Was andere Nutzer sagen

Anmerkungen

Abschnitt "Für alle Fachrichtungen"

Fachrichtungen: Allgemeinmedizin, Anästhesiologie (Anästhesisten), Anatomie, Arbeitsmedizin, Augenheilkunde (Augenärzte, Ophtalmologen), Gefäßchirurgie, Herzchirurgie, Kinderchirurgie, Orthopädie und Unfallchirurgie, Plastische und Ästhetische Chirurgie, Thoraxchirurgie, Visceralchirurgie, Frauenheilkunde und Geburtshilfe (Gynäkologen, Frauenärzte), Schwerpunkt Gynäkologische Endokrinologie und Reproduktionsmedizin, Schwerpunkt Gynäkologische Onkologie, Schwerpunkt Spezielle Geburtshilfe und Perinatalmedizin, Hals-Nasen-Ohrenheilkunde (HNO-Ärzte), Sprach-, Stimm- und kindliche Hörstörungen, Haut- und Geschlechtskrankheiten (Hautärzte, Dermatologen), Humangenetik, Hygiene und Umweltmedizin, Innere und Allgemeinmedizin (Hausärzte), Innere Medizin, Angiologie, Endokrinologie und Diabetologie, Gastroenterologie, Hämatologie und Onkologie, Kardiologie, Nephrologie, Pneumologie (Lungenärzte), Rheumatologie, Gebiet Kinder- und Jugendmedizin (Kinderärzte), Schwerpunkt Kinder-Hämatologie und -Onkologie, Schwerpunkt Kinder-Kardiologie, Schwerpunkt Neonatologie, Schwerpunkt Neuropädiatrie, Kinder- und Jugendpsychiatrie und -psychotherapie, Laboratoriumsmedizin, Mikrobiologie, Virologie und Infektionsepidemiologie, Mund-Kiefer-Gesichtschirurgie, Neurochirurgie, Neurologie (Nervenärzte), Nuklearmedizin, Öffentliches Gesundheitswesen, Pathologie, Neuropathologie, Pathologie, Pharmakologie, Klinische Pharmakologie, Pharmakologie und Toxikologie, Physikalische und Rehabilitative Medizin, Physiologie, Physiotherapie (Physiotherapeuten), Podologie, Psychiatrie und Psychotherapie (Psychotherapeuten), Schwerpunkt Forensische Psychiatrie, Psychosomatische Medizin und Psychotherapie, Radiologie, Schwerpunkt Kinderradiologie, Schwerpunkt Neuroradiologie, Rechtsmedizin, Strahlentherapie, Transfusionsmedizin, Urologie ↩

Unsere zahlreichsten tomedo® -Ärztinnen und -Ärzte sind Allgemeinmediziner, Chirurgen, Dermatologen, Gynäkologen, Augenärzte, Radiologen, Phlebologen, Internisten, Neurologen, Psychiater, Psychotherapeuten, HNO-Ärzte, Anästhesisten, Orthopäden und Poolärzte und die entsprechenden ‑innen. Auch Heilpraktiker(innen) sowie Osteopathen, Podologen und Physiotherapeuten haben wir viele. ↩

Ohne Zusatzkosten ist eine Anbindung an Geräte wie EKG, Sono oder Ergometrie über GDT, BDT, DICOM und andere Schnittstellen möglich. ↩

Durch die Datenbank-Konvertierung aller gängigen Praxissysteme garantieren wir Ihnen einen sorgenfreien Umstieg, auch wenn Sie bisher auf eine Windows-Software zurückgreifen mussten. Jeder Schein, Karteieintrag und -Anhang aus Ihrer alten Arzt-Software bleibt bestehen und ist mit tomedo® nun leichter zugänglich als je zuvor. Damit Sie vor Ihrer Entscheidung für tomedo® darüber Gewissheit erlangen und später vor der Umstellung ruhig schlafen können, führen wir zunächst eine kostenlose und unverbindliche Testkonvertierung durch, deren Ergebnis wir Ihnen in einer tomedo®-Probeversion zur Verfügung stellen, mit der Sie unbegrenzt lang „spielen“ können. ↩

Wir führen Konvertierungen aus ABOMED, Albis, Apris, APW / Arztpraxis Wiegand, Archilino / x.archilino, Arcandus (Arkandus) / Systemraum, Arcos / CompuMED, CoKom Archiv / CoKom, Data-AL / Zimmer-AL, DataPrax / MedVision, David / Data Vital, DC Patho und DC ROSS / dc systeme, DKCS, doc@rchiv / docarchiv, DOCexpert, DOCcomfort, x.comfort, DOCconcept, x.concept, Dorsymed / CompuMED, Duria, Easymed, Easywin / Promedico, EL (E.L. – Elaphe Longissima) / Softland, Elefant / Hasomed, Elmed / Kups, Epikur, eRIS / Digithurst, EVA / Abasoft, GENOprax / GENOdata, Happy-Doc / Elbatron, Iatro pro, Iatrosoft / Frühwald, ifa / ifasystems, INA / MCS, Indication / ET Software, Informed, INORIS / NEXUS, InterArzt / InterData, InterMediNet / DBI, Intramed / BIOSYSTEMS, ISYNET / MCS, ixx.comfort, ixx.concept, isynet oder x.isynet / J-MED / MDI, Kauz / iSoft, KIWI / Kind, KV-Med / Pharmatechnik, L1 / Lohse, Leisys / DOCexpert, Linumed / Pharmatechnik, Lorenzo / iSoft, M1 / CompuMED, MAP / Saltron, MCS-INA / MCS, MCS-Isynet oder x.isynet, Medavis RIS / Medavis, medibit / Arzt & Praxis, MED7 / Bitron, Medical Office / Indamed, mediDOK, Medipas / IMC, medi10 / Pharmatechnik, medicPC / BIOSYSTEMS, MEDISTAR, MediWORKS / MediTec, MeDO, MeDO.med, MeDO.win / Data Control, MedWinner’s / MedWinners, MEDOS, Medys 9, Medys 10, MovieStar, multiMED / Varicom, Nephro 7 / MedVision, NEXUS / RIS, Onmed / CompuMED, PDE-Top / MCS Pie Data, Pegamed / Pega, Praktisch / Klaus, PraxisArchiv / Z1, PraxisTimer / Z1, Prisma / RS Datentechnik, Profimed / Promedisoft, Pro Medico, Pro_Medico / Neutz, PRO MED / promed, QMED.PRAXIS, Q-med / Schwerdtner Medizin-Software, Quincy Win, Quincy.med, Quincy PCnet/ Frey, RST-MED / Steinbrecher, S+N, S1 und S3 / Mediamed / Systec, Sisymed / DOCexpert, star.net / GLP networks, starc, Sysmed-KDV / CompuMED, TurboMed, Vestiga, V-doc / CompuMED, WinRadiolog / AKOSYSTEM, Zytomaster / Paschmann durch. Am häufigsten stellen wir derzeit Turbomed, Medistar, Albis, Medys und M1 auf tomedo® um. Einen T2Med-Konverter haben wir noch nicht, ist aber in Arbeit. ↩

Die Lizenz der KBV legitimiert tomedo® offiziell als Praxis-Software zur Medikamentenverordnung gemäß AVWG, Online-Abrechnung für Kassen- und BG-Ärzte (inkl. Dale-UV-Anbindung), 1-Klick KV-Connect / KV-Safenet, e-Arztbrief, DMP-eDoku, Früherkennungskoloskopie, Labordatenimport und Blankoformulardruck. Auch die elektronische Dokumentation des Hautkrebs-Screening (HKS-eDoku) ist in zahlreichen dermatologischen Praxen erfolgreich im Einsatz. ↩

tomedo® ist in allen Bundesländern (auch Bayern und Baden-Württemberg) für die Hausarztzentrierte Versorgung (HzV) per HÄVG und für die meisten S3C-Verträge einschließlich Grünklick zertifiziert. ↩

Falschschreibungen: Toledo, tomato, tomado, tometo, tomed ↩

Abschnitt "Einzigartige Funktionen"

Diktieren Sie mit der tomedo®-Spracherkennung einfach und zeitsparend alle Karteieinträge, Briefe, Formulare, etc. Die Spracherkennung wurde von unserem KI-Team entwickelt und beherrscht den medizinischen Fachwortschatz. Mit der Sprachsteuerung können Sie u.a. Karteieinträge und Formulare aufrufen bzw. anlegen. ↩

Online-Termine können durch Zuweiser oder den Patienten selbst direkt über Ihre Praxiswebseite in den tomedo®-Kalender gebucht werden. ↩

Abschnitt "Weitere Funktionsbereiche"

Bei Fehleingaben von Leistungen und Diagnosen werden Sie sofort an Ort und Stelle sowie in einer global einblendbaren sich selbst aktualisierenden Prüfmodul-Liste gewarnt und können diese beheben. ↩

Über einen Klick wird eine PAD-Abrechnungsdatei auf Ihren Schreibtisch gelegt, die Sie bequem per Mail an Ihre private Verrechnungsstelle (PVS) schicken. ↩

Ihr Patient unterschreibt Anamnese- und Aufklärungsbögen sowie Einverständniserklärungen auf dem iPad. Mit der Unterschrift wird auch die Drucksensitivität gespeichert, was die Rechtssicherheit Ihrer Dokumentation steigert. Die elektronische Signatur wird damit nahezu fälschungssicher mit den Formulardaten in der tomedo®-Datenbank hinterlegt. Voraussetzung hierfür ist entweder ein Stylus der Marke „Bamboo Fineline 2“ von WACOM; oder das iPad Pro mit dem Apple Pencil. ↩

Zur Unterstützung und Beschleunigung des Anmeldeprozesses bieten wir Ihnen ein Patiententerminal zur automatischen Selbstanmeldung. Mittels eines für Patienten zugänglichen Rechners in der Praxis können sich diese selbstständig anmelden, indem sie ihre Chipkarte stecken oder ihre Kenndaten eingeben. Danach können sie, wenn gewünscht, noch ihr Foto aufnehmen, Telefonnummer und E-Mail-Adresse aktualisieren und einen Anamnesebogen ausfüllen. So kann in vielen Routinefällen, wie z.B. Patienten, die einfach nur zum vereinbarten Termin erscheinen, die klassische Anmeldung entlastet werden. Reduziertes Schlangestehen kann die Patientenzufriedenheit steigern und den Stress der Mitarbeiter mindern. ↩

Unter der Anleitung mehrerer Dermatologen haben wir für die Hautkrebsvorsorge das Video- und Bilddokumentationssystem intellimago entwickelt. Zusammen mit einem Handy-Dermatoskop (einem iPhone-Aufsatz) unterstützt Sie intellimago bei der Nävi-/Muttermal-Kontrolle (sowohl chronologischer Vergleich als auch Begutachtung der Gefahr maligner Melanome). ↩

Speziell für Allgemeinmediziner haben wir ein eigenes Impf-Modul entwickelt, das ohne Aufpreis verfügbar ist. Alternativ bieten wir eine Anbindung an ImpfDocNE vom Deutschen Zentrum für Impfmedizin, ein mächtigeres Programm, das für Sie immer gemäß aktueller STIKO-Empfehlungen Impfpläne erstellt – inklusive Reiseimpfungen und Postexpositionsprophylaxe. ↩

Features:

- Automatisierte Impfplanerstellung

- Aktuelle Länderinformationen bei Reiseimpfungen

- Berücksichtigung von Vorimpfungen und Gefährdungsgrößen (Vorerkrankungen, Dauerdiagnosen etc.)

- Integriertes Warnsystem

- Lagerhaltung für Ihre Impfstoffe

- Impfdiagnosen und Ziffernketten, die automatisch in die tomedo®-Abrechnung übernommen werden

- Impf-Terminplaner, Recallsystem, Aufklärung

Über einen blinkenden Warnhinweis werden Sie zur richtigen Zeit an anstehende Untersuchungen wie den allgemeinen Gesundheits-Check-Up ab 35 erinnert. ↩

Bei der Textverarbeitung für beispielsweise die Arztbriefschreibung unterstützen wir MS Word sowie das kostenlose LibreOffice für Mac OS. ↩

Ein VPN-Tunnel ist eine Software, die es ermöglicht, sich aus einem Netzwerk (z.B. von Zuhause) in einem anderen privaten Netzwerk (Ihrer Arztpraxis) anzumelden, ohne ein Sicherheitsrisiko einzugehen. ↩

Automatische 1-Klick-Terminsuche, Berücksichtigung von Sprechstunden-Zeiten, Besuchsplanung über To-dos, Terminketten, Urlaubsplanung, SMS-Erinnerungen – hier ist alles möglich, was Sie sich vorstellen können. ↩

Mit tomedo® profitieren Sie von allen Mac-OS-Updates, ohne auf Funktionalität verzichten zu müssen, denn wir garantieren Ihnen uneingeschränkte Kompatibilität mit allen zukünftigen Mac OS X-Versionen. Wenn Sie immer auf dem neuesten Stand sind, sind „Viren“ oder „Abstürze“ für Apple-Computer Fremdwörter und Ihre Daten sind immer optimal geschützt. ↩

Unser Expertenteam garantiert Ihnen durch die Zusammenarbeit bewährter Kodierungsmethoden, modernster Datensicherungen und Macs nativem Schutz, dass Ihre sensiblen Patientendaten auch sensibel behandelt werden. ↩

Ohne ein IT-Spezialist zu sein, können Sie über unsere tomedo® Server-App eigenständig Sicherungen erstellen, automatische Backups einstellen und im Notfall über wenige Klicks eigenständig einspielen. ↩

Müssen Sie z.Z. ein externes Praxis-Archiv-Programm zur Dokumenten-/Bildverwaltung nutzen? Oder regelmäßig Karteikarten archivieren, weil die Praxissoftware sonst zu langsam wird? Bei uns gilt „Archivierung“ als Schimpfwort; alle Dokumente eines Patienten befinden sich direkt in seiner elektronischen Patientenakte und werden automatisch im Hintergrund nachgeladen. Jede Änderung an der Krankenakte oder einem Dokument speichert tomedo® automatisch revisionssicher auf dem Server ab. Außerdem enthält tomedo® noch eine Aufgaben-Verwaltung und ein Qualitätsmanagement (alles ohne Aufpreis). Dort können Sie jeweils Dokumente einpflegen, die sich auf die gesamte Praxis beziehen, und bestimmten Mitarbeitern oder Mitarbeitergruppen zum Lesen oder Bearbeiten zuweisen. ↩

Abschnitt "Grenzenlos mobil"

Hat Ihr Mac, iPad oder iPhone keine aktive Netzwerkverbindung, dann arbeitet tomedo® unabhängig im Offline-Modus weiter. Sobald die Verbindung zum Server wieder hergestellt wurde, werden all Ihre Änderungen automatisch auf den Server eingespielt. ↩